|

WATERTIGHT

CYLINDER (WTC) - An Overview

|

1.

The heart of any radio controlled submarine is the

watertight cylinder, or WTC. Whether you choose to build

your own or buy a custom unit, the basic elements remain

the same. As previously noted, the optimum size for the

Permit hull is a 3" diameter cylinder.

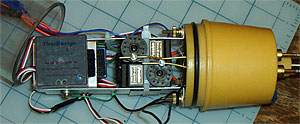

The D&E Miniatures WTC-3 depicted here consists of

three compartments: battery, ballast tank and propulsion

(l-r). |

|

2.

The Battery Compartment is accessed through a removable

forward bulkhead. Inside is the battery, usually a 6

cell NiCad pack. It is connected to the electronic speed

control, in this case a ThorDesign

SC-10 Speed Control. The SC-10 is then connected

to the motor by wires which run through a watertight

tube passing through the adjacent Ballast Tank to the

aft dry space. It is recommended that a fuse be installed

in-line between the battery and motor. A second lead

runs from the SC-10 to the receiver in the aft compartment.

This supplies power for the electronics via the SC-10's

built-in battery eliminator circuit (BEC).

|

|

3.

Located between the Battery and Propulsion compartment

is the Ballast Tank. The system pictured features a copper

bottle which is charged with a compressed gas (Propel)

which is used to purge water from the tank. The tank's

bottom is open to allow free flooding and draining. At

the top is a valve which opens to vent the tank. A servo

mounted on the dry side of the aft bulkhead operates both

the vent and blow valves. The blue-white foam object in

the tank is a float which monitors the water level and

prevents excess blowing of gas when the tank is dry. |

|

4.

The Propulsion Compartment is accessed through a removable

rear bulkhead. Mounted in the bulkhead is the electric

motor and reduction gear. A 3:1 reduction works well for

a 1/96 Permit class boat. Reduction gears reduce

the work load on the motor and thus extends the run time

for the battery. The radio receiver is mounted on the

underside of the electronics rack attached to the removable

bulkhead. |

|

5.

The receiver processes the radio signals and sends commands

to the servos. Two servos are connected to the linkages

for the rudder and stern planes. Their control rods

pass through the stern bulkhead using watertight seals.

|

|

6.

An essential piece of electronics is the angle keeper.

It is mounted between the receiver and the stern plane

servo. The most advanced unit of its kind is the ThorDesign

PC-2A

Pitch Control. Using an accelerometer, the

PC-2 senses the boat's attitude and sends corrective

action to the stern planes to keep a zero bubble. It

is essential that PC-2 be mounted level in the WTC.

|

|

7.

Another in-line device is MicroSafe,

a micro-sized failsafe. MicroSafe is connected between

the ballast tank blow servo and the receiver. It constantly

monitors the radio signal being received. In the event

the signal is lost, it automatically commands a blow of

the ballast tank, following a preset delay of several

seconds, and the boat surfaces. Never operate submerged

without a MicroSafe. |

|

8.

Here the stern bulkhead exterior can clearly be seen.

The receiver antenna exits the bulkhead and it's connector

is covered in silicone to ensure watertightness. The

antenna is looped within the wet area of the hull. The

watertight seals for the drive shaft (centered) and

two control shafts can also be seen. With the WTC and

drive train installed, the next step in assembly is

connecting the model's control surfaces to their servos...

|

| |

Linkages

|

|

|

Details,

Details

Most

manufacturers of WTC's, such as D&E Miniatures,

include a setup and operations manual with their units.

The information given here is intended as a supplement,

not a replacement, for those specific manufacturer instructions.

|

|

A

Word To The Wise

Never

use a lead acid or "gel cell" type battery

in a dry WTC compartment. Gel cells can give off hydrogen

gas under normal operating loads or when charging. If

this highly flammable gas comes in contact with a spark

generated by the motor or other electronic device, the

results can be catastrophic. Always use a NiCad or NiMH

type battery pack in enclosed WTC compartments.

|

|