|

|

1.

With a 3/32" bit in the chuck, drill the mounting

hole for the upper rudder bearing. It's exact location

is the dimple in the upper stern. |

|

|

2.

Turn the hull over and drill the hole for the lower

rudder bearing. Again, a dimple in the hull indicates

the exact drill point. |

|

3.

Insert a length of 1/8" o.d. (3/32" i.d.)

brass tubing into the upper rudder bearing hole. Extend

the end of the tubing through the bottom rudder bearing

hole until it is flush with the exterior of the hull.

Then mark the tubing with a sharpie at the upper rudder

hole so the mark is flush with the exterior of the hull. |

|

|

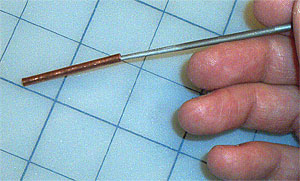

4.

Using a K&S (or other similar) tubing cutter,

cut the tubing on the sharpie mark. |

|

5.

De-burr the freshly cut end of the tubing with a small

round needle file. The control shaft of the rudder

pieces should be able to slip into each end of the

tube and rotate without binding. |

|

6.

Slip the tube back into the holes in the hull and insert

the rudders in the top and bottom. |

|

7.

Make marks on the tube with a sharpie approximately 1/8

inch from the hull on both ends. |

|

8.

Cut the tube on each mark with the tubing cutter.

The two small pieces will be used as the upper and lower

rudder bearings. Do not discard the center section

of the tube. It will be used in the gluing process.

De-burr all three pieces of tubing with a round needle

file to ensure that the rudder control shafts do not

bind. |

|

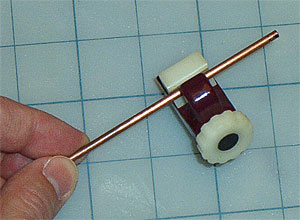

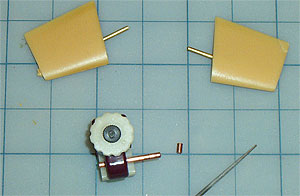

9.

Place the bottom rudder in the hull with the small bearing

on the shaft. Slip the longer, middle tubing piece over

the shaft. With the small upper bearing on the control

shaft, insert the upper rudder into the hull and the

middle connecting tubing. NOTE: the image at left depicts

how the rudders and bearing/tubing pieces will be arranged

in the hull during the gluing process.

The

middle brass tubing piece, though it won't be used in

the final operational rudder setup, serves to keep the

bearings properly located in the hull holes for gluing

and also keeps the upper and lower rudder control shafts

properly aligned. |

|

10.

Visually check the rudder alignment at this time.

When viewed from astern, the rudders' trailing edge

should form a vertical line through the center of the

hull. If any correction needs to be made, use a round

needle file on the hull holes. NOTE: a little filing

goes a long way on the alignment of these holes. Work

carefully. Once everything checks out, it is time to

glue the bearings in place...

|

| |

Next |