|

DETAIL

& PAINT - Detailing The Boat

|

Deck

Fittings - Permit kits come with a selection

of white metal parts to represent all the major deck

fittings such as cleats, windlasses, etc. The hull is

molded to represent these fittings in their retracted,

at-sea positions. To depict them in their extended positions,

drill a pilot hole for each fitting in the upper hull

and file out the opening. Clean the flash from the white

metal part and insert it in the proper hole. From the

back side, apply epoxy to glue it in place.

|

|

Stern

Light - 1. Drill a hole in the upper rudder to accept

the white metal part depicting the stern light beacon.

|

|

2.

Apply a drop of CA to the bottom of the stern light part

and insert it in the hole. |

|

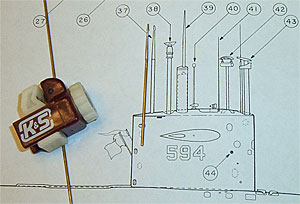

Periscopes

& Masts - An assortment of resin and metal parts

are included to depict the various periscopes and masts.

Using the plans, drill and file out holes in the sail

top for the masts you wish to install.

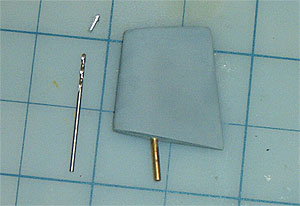

1.

For this project only the single attack periscope was

used. Cut a length of brass tube to represent the periscope

barrel. Clean the white metal periscope top and glue

it in one end with CA.

|

|

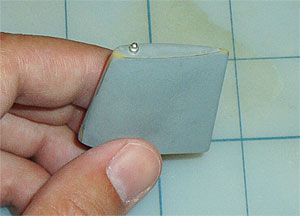

2.

Next, drill a hole in the sail top. Insert the periscope.

Friction will hold it in place during patrols. For other

masts, insert a small threaded rod in the bottom of the

mast. A washer and nut can then be applied from the inside

of the sail to hold it in place. |

|

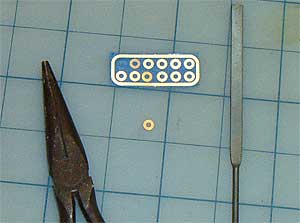

MBT

Vents - A tree of stainless steel photo-etched

Main Ballast Tank vents are supplied with the

kit.

1. Cut

or twist a vent from its tree. File off any rough

edges. Due to their tiny size, it is best to hold the

part with a pair of needle nosed pliers. To increase

grip and avoid scratching the part, wrap masking

tape around each half of the pliers. |

|

2. Place

a drop of CA in the beveled part of the MBT vent then

insert the photo-etched part. It should lay flat with

the hull's surface. Early Permits had their

stainless steel vents painted black but at sea the

paint would quickly wear off. As a result, they

were left unpainted starting in the mid 1960's. |

| |

Zincs

- Once the final paint job is finished, the

zincs should be affixed to the stern. Their location

is indicated on the plans and scribed in the hull.

Place masking tape on either side of the scribe mark,

apply CA to the underside of the metal part and lay

it between the tape in the proper location. This

prevents the glue from damaging the adjacent paint.

As full scale zincs were unpainted, leave these parts

in their raw, white metal condition. |

| |

Next

|

|

|

Which

Permit?

The

ThorDesign Permit kit depicts USS Permit

(SSN-594) in it's as-built condition circa 1962. However,

the boats of this class served well into the 1990's

and underwent many modifications. To properly detail

your model, chose the specific boat and service period

you wish to depict and research her thoroughly. For

the purpose of these instructions, we chose to model

USS Thresher (SSN-593) at the time of her loss

on April 10, 1963.

The

following boats made up the Permit class:

- SSN-593

Thresher

-

SSN-594 Permit

-

SSN-595 Plunger

- SSN-596

Barb

- SSN-603

Pollack

- SSN-604

Haddo

-

SSN-605 Jack

-

SSN-606 Tinosa

-

SSN-607 Dace

- SSN-612

Guardfish

- SSN-613

Flasher

-

SSN-614 Greenling

- SSN-615

Gato

-

SSN-621 Haddock

|

|